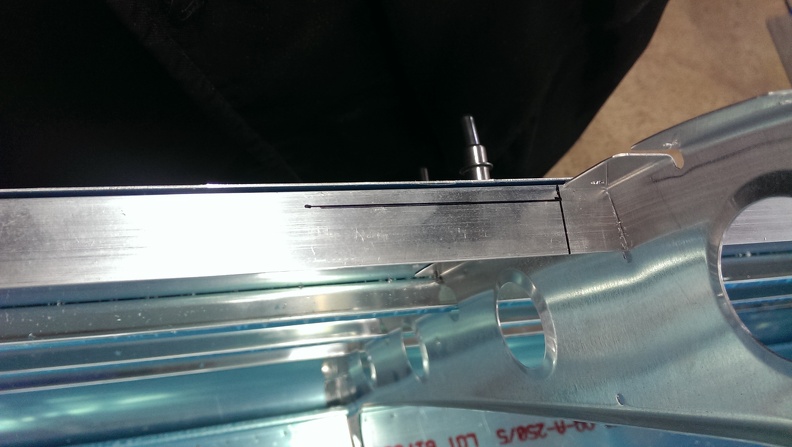

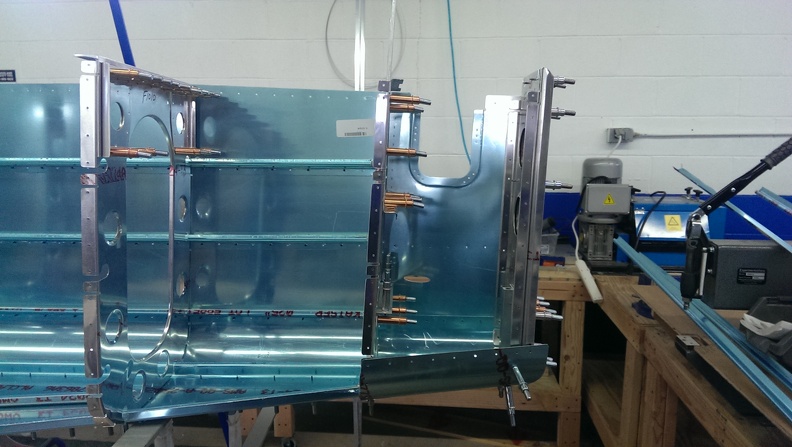

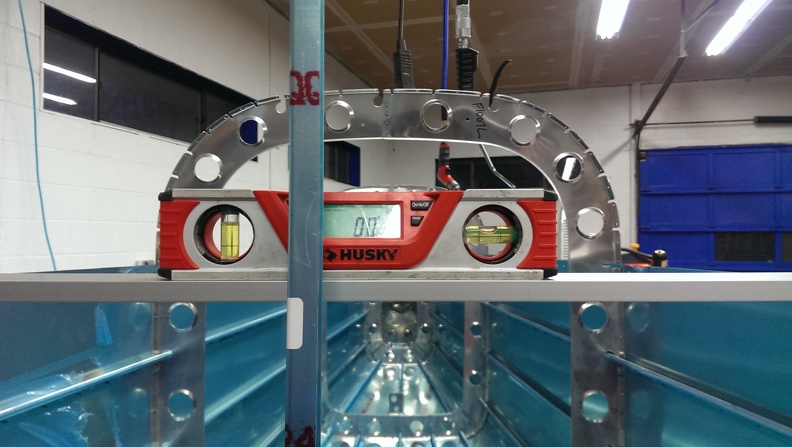

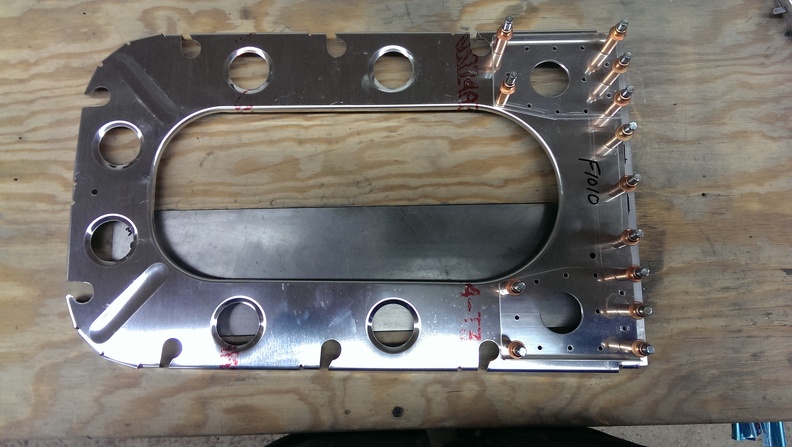

Today I started by counter sinking the Longerons. This was going swimmingly till the shank on my counter sink got stuck and broke with only 3 holes left. While that was pretty depressing, it left me with few things I could work on till a replacement came in. The elevator bellcrank assembly was pretty easy. I had to cut apart the pieces and deburr the edges. That was followed by match drlling everything and priming them. I also ended up priming the F1085? rudder cable bracket as well

Since it was getting late I hopped on Cleaveland Tools web page and ordered a some countersinks, a dedicated deburing tool, stainless tie down rings, tail light adapter ring, Push on Static Ports, and some 1″ 3m wheels.

I am ordering the SafeAir1 Pitot-Static kit, but I don’t like the way the SA1 Static ports look.