Today I sanded all the parts that I had available. The ability to use my palm sander made it a million times faster. I also ordered a bunch of red scotch brite pads from amazon as well. That is the only down side of the palm sander is it tears the pads up pretty quickly. After sanding I dimpled one of the skins for the horizontal stabilizer. I can’t stress about how there is a lot of holes in this thing. One step at a time though. No pictures tonight.

Month: January 2014

Shop Upgrade

As I said in my last post, a drop cord would come in handy. This got the brain tinkering and I came up with a plan. Not only would I install a drop cord, but I ordered 2 Retractable Air Hose Reels from Amazon. After a quick run to home depot I grabbed a 25′ air hose, 30′ of 1/2″ EMT, and some 3/8″ black iron pipe and various other pieces I went to town. I already had the drop cord from previous adventures, and I have several thousand feet of wire in the warehouse, so I saved some cash there. Over the last few days I slowly installed a new electrical circuit to right above my work area. I also hung and ran the feed hose for my new hose reels. I think this will be extremely helpful in the future.

Match Drilling & Disassembly

Today I finished the other half of the Horizontal Stabilizer. Once that was completed I disassembled everything. It’s so amazing how compact this part is when its disassembled. After dreading scotch briting the entire surface, I discovered that my palm sander will hold a scotch brite pad pretty well. This led to the next problem, Electricity. This would be far easier if I had a drop cord.

Match Drilling

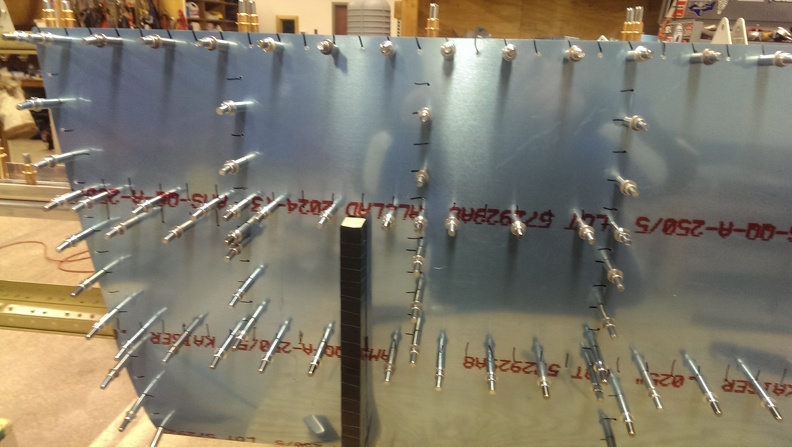

Ran out of Clecos!

Front Spar Construction

Today I primered & assembled the Front HS Spar. I did learn a valuable lesson here that I will probably forget. But its basically, If there is another tool, its probably the right tool. The adjustable set holder for the rivet squeezer is pretty much at its max for a -9 rivet. But I got into my rhythm I forgot I had my rivet gun that I could use. Had I used this, I think this would of gone far easier on the -9 and -10 rivets.

Nezr I added the various ribs to the spar and matched drilled as neccessary

Me cleco’ing

Nice pretty rivets, I bet you can’t tell without looking at my other post which holes I fixed

Countersink Fix

HS Front Spar, Ribs, & Skins

On Friday I called Van’s and spoke with tech support. After describing the issue, I was advised that a -4 rivet could be put in place instead. When I asked about the -4 still being too deep, We reviewed the plan’s again and determined that since all it was holding was the stiffner, Which is riveted closely on both sides, as well as the vertical portion. I could “patch” the hole with JB Weld and redrill it. This is NOT recommend for key places. I apparently got really lucky and it would not be an issue.

I took some tape and created a seal so the JB Weld would not drop through and be smooth. I also filled in a 2nd rivet that was just a LITTLE deep, not bad at all. I smoothed it out as best I could, the rest will need to be sanded down a bit.

While waiting for this to dry I went on to the next set of parts that I could work on. The plans have you modify 4 HS-1004 ribs. This was pretty easy. Just cut some minor sections out as well as bending 2 of them. Next I grabbed the HS-905 ribs and began deburring them. This is the first section of the plans that really confused me. The parts they send you do not look like the parts in the plans. Van’s has apparently added lightening holes to each of the nose ribs and you no longer need to cut the oval as described in the plans. After painfully removing the blue plastic from everything, I deburred the edges of all the ribs that I had worked on so far.

Next I fabricated 4 cradle stands and wrapped them in black vinyl electrical tape to protect the skins. Finally I skipped ahead of the plans and cleco’d the nose ribs in. Looks like I will be taking these out when it is time to work on the spar again.

HS Continued

Today I began by cleaning & priming the components I made so far. The process is relatively simple. Wash with Dawn soap. I use one of those handle/sponge things you can get anywhere. Next I rinse it in a bucket of fresh water. Next I take a small container filled with POR-15 Metal Ready and brush it on to every exposed surface of material. After letting it sit for 30 minutes I dump the pieces into the last fresh water tank. Next, I will sit the pieces out to dry. If parts are exceptionally damp I will hit them with a towel to absorb as much moisture as possible. Once that is done, I’ll spray it with SEM EzCoat Primer. As I’ve said before, this stuff dries incredibly fast! I’ve literally watched it dry before my eyes.

Part’s coated in acid waiting to be washed

Parts waiting to be primed

Parts Primed, Ready to Rivet

The rear spar riveted and “complete” for this step

Since I had plenty of time let, I decided to continue on to the next step that I could do.

Next I had to cut and deburr the HS-1013, HS-1014, & HS-1015 stiffners. This was long and boring but had to be done. Next the plans have you mark a 1/4″ line on the 2 HS-1013 stiffners and line them up with the 33rd hole from the edge of the spar & clamp them in place. Next you begin the process of match drilling. Once complete, the HS-1007 Spar doubler gets added as well as the HS-1008 attachment plates. It took me a little while but I found a old mounting bracket for some Andrews Diplexer’s ( I doubt anyone will find one of these ) to hold the entire assembly to the table. Once everything was locked down I did some more match drilling.

While countersinking the 9 center holes on the top half, I had not noticed the microstop counter sink got jammed and the “gate” was set far deeper than I wanted. When I was countersinking the first hole it popped free, and was a relatively deep counter sink. I will ask van’s about it in the morning.

Horizontal Stabilizer start!

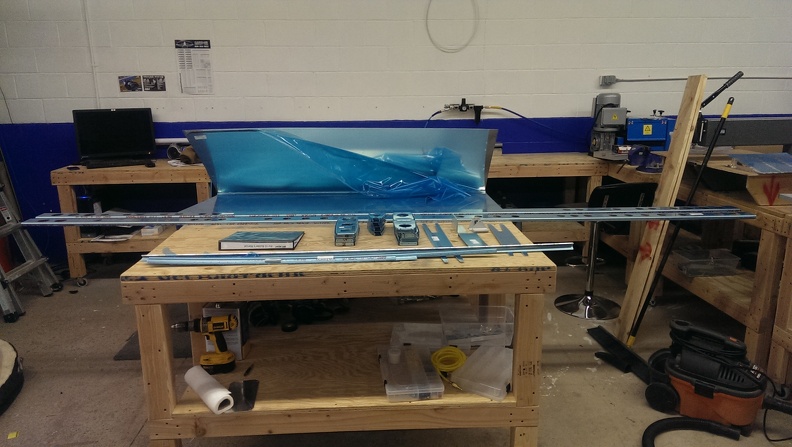

Today I started by gathering all the parts for the horizontal stabilizer. This is where things really start to get big. I can also tell that this area clearly gets hit with a lot of force as everything is far thicker than everything else I’ve put together. The spar’s clock in at just over 11′ long!

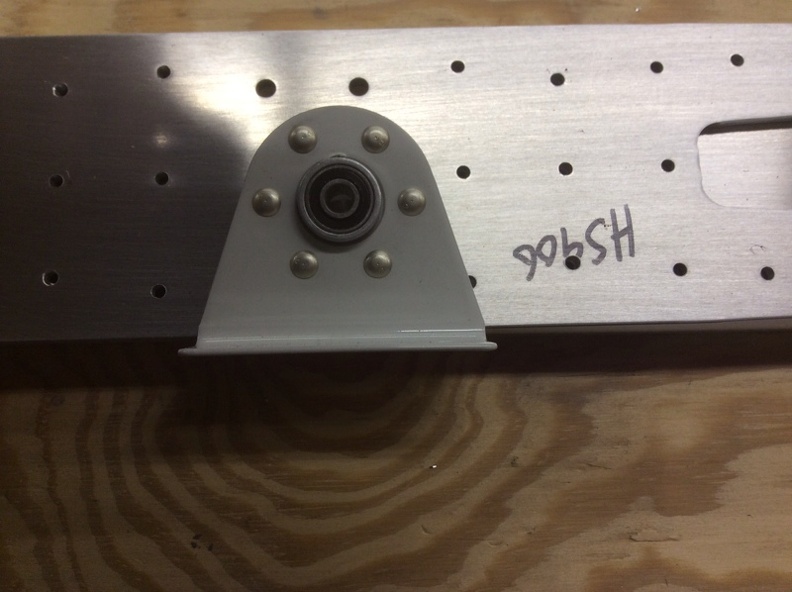

I really didn’t take many pictures in order as I have been trying to do. First I took off the plastic on the HS1003 Rear Spar & the HS906 Rear Spar Doubler. Next I cleco’d it together, and began to match drill all the holes per the plans. After counter sinking the 2 holes in the center and deburing every hole, I began match drilling the hing brackets. After that was done I deburred the edges (Step 1) and scruffed the pieces for primer.

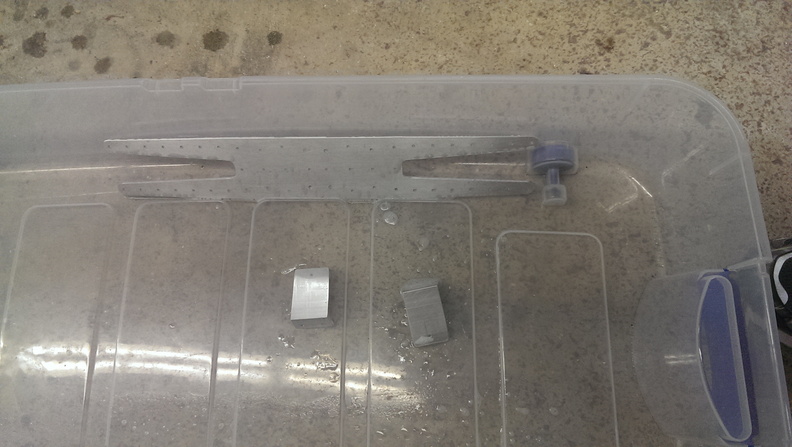

Since I had no desire to prime today, I continued ahead with the plans. The next thing was the flange bearing. This was incredibly easy to do and I spent more time grabbing tools then I did working on the piece.

Since I couldn’t attach the flange bearing to the rear spar, I skipped another step. Steps 3 & 4 on pg 8-3 are essentially the same. You make the same piece (HS1008 Front Spar Attach Bracket) but they are opposite sides. I think the amount of time I saved on the flange bearing went into in these 2 pieces. You take a 6″ long x 2. 1/2″ tall x 2″ deep angle aluminum and cut it down every which way possible. This really wasn’t difficult compared to some of the things I used to machine years ago. But still time consuming.

Everything waiting to get primed for now