Over the last 2 weeks I ahven’t done anything large by any real standard and its hard to post about putting a screw in here or there. So i’m just going to add it all into one post.

- Installed the Trim Servo & Cables. Eventually took the trim servo out so I could connectorize it. That still needs to go back in. I forgot to order the cases for the DB9 connectors and those will be here Monday.

- Need to figure out why the left elevator trim will not go as high as the right side. It barely goes above the left elevator, but is even when in the down position.

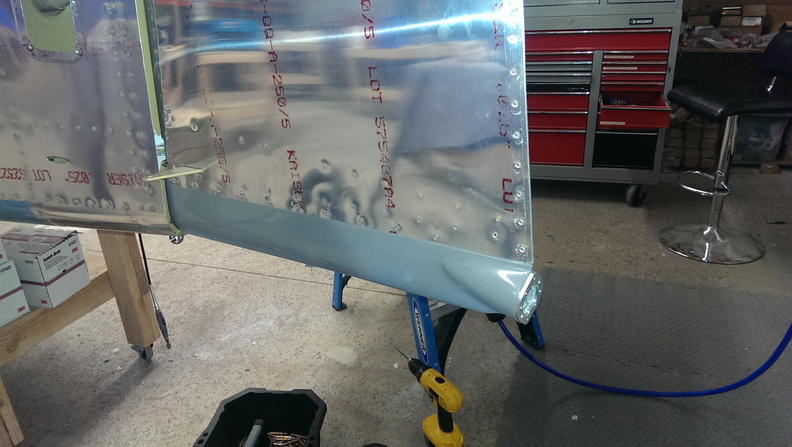

- Mounted all of the elevator & rudder fairings.

- While installing the bottom rudder fairing I installed the Rear Strobe Mounting bracket I received from Cleveland Aircraft Tool. This is a nice looking bracket that should make strobe mounting a breeze.

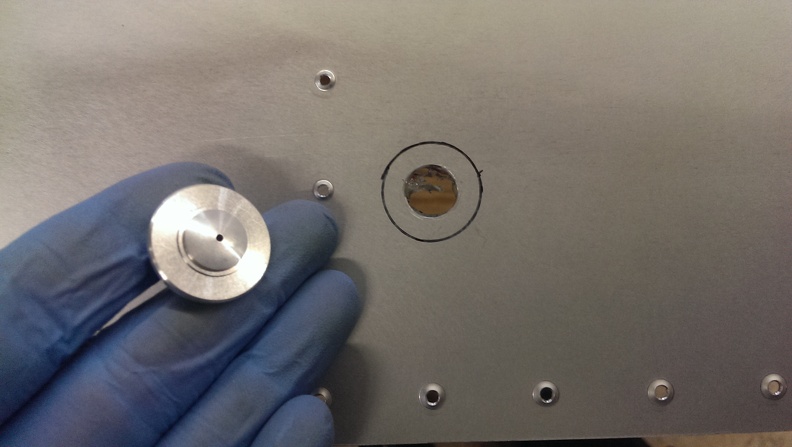

- Installed the Flush Static Air ports from Cleaveland Aircraft Tools

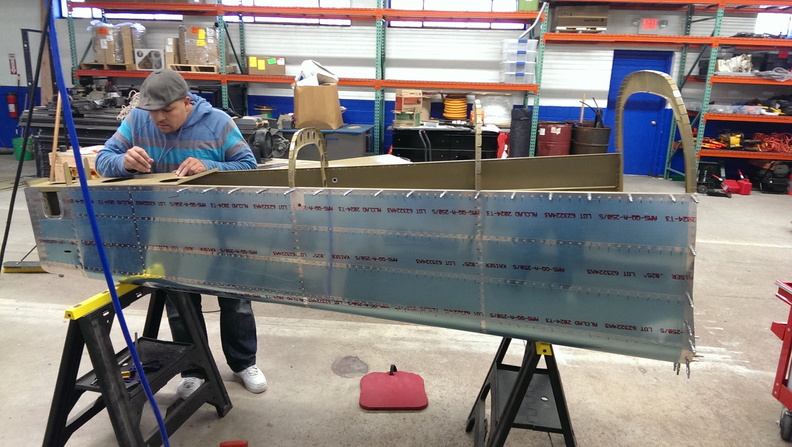

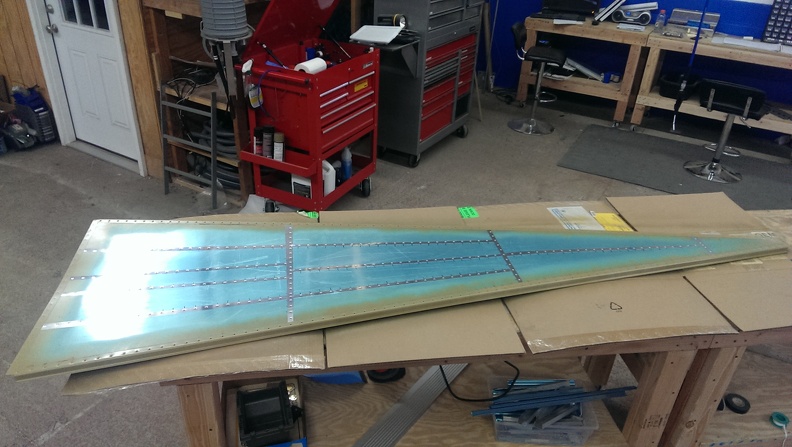

- Rebuilt the right trim tab. This looks much nicer then the old one. Still need to do the left side

I also going to create a tasks to do page. So I can easily remember what I still need to do for when i skip steps or move onto other areas if I get bored.