Today I ran over to Home Depot and picked up some new Dewalt 20V Drills. I really did not want to buy any of the 20V stuff, but they stopped producing the one drill I needed in 18V. So I ended up getting the 20V 90d Angle Drill (tool only) and a combo kit that had a 1/4″ impact, drill/driver, 2 batteries, a charger and a bag. Once I got to the shop I immediately tested out the 90 degree drill and it did exactly what I needed it to do. I was able to drill out the conduit holes that I neglected to do earlier. This was followed up by tidying up the shop a little bit.

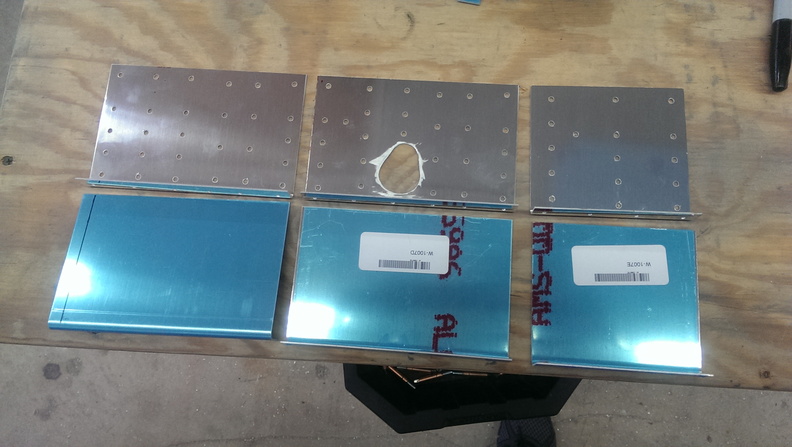

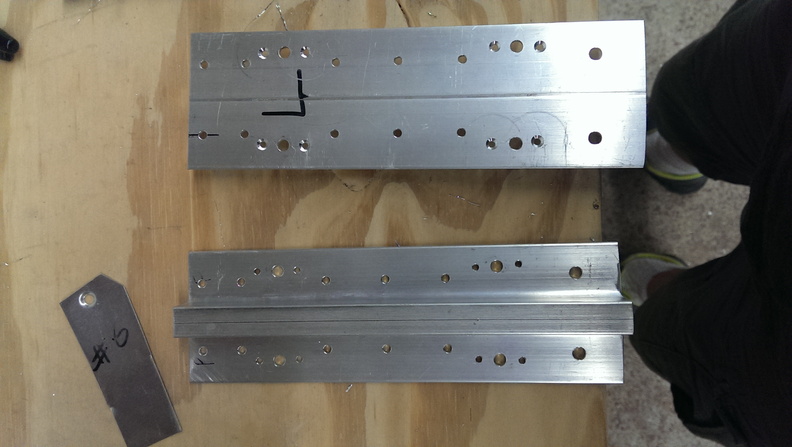

Next I grabbed the rear spars and mounted the doublers to them and began match drilling. After match drilling one spar, I had to make a hole in one of the doublers match the spar. My solution was to use a unibit to take out a big chunk of the material and then dremel the rest out. With a cutting blade I cut out what i could. then i cut little notches to the edge. Next I used a dremel drum sander to smooth out the roughness.

next i mounted the spars to the ribs and matched drilled those

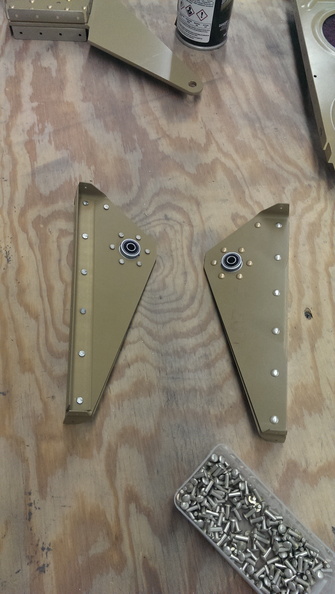

once that was completed I began disassembling and deburring, cleaning and priming. Once the primer was dry I cleco’d everything back together and began riveting.