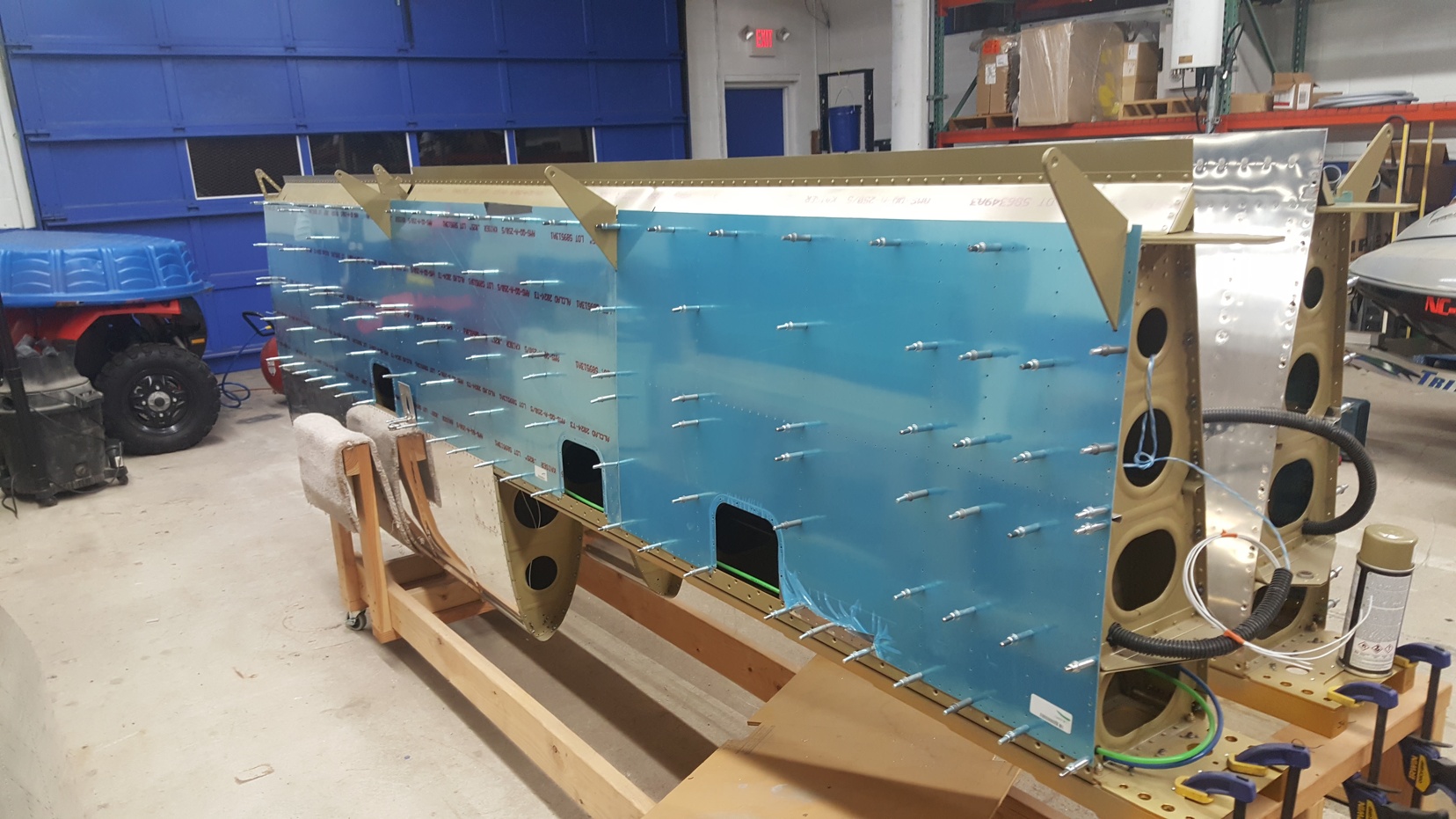

Today I came in finished priming the bottom wing skin parts that I had yet to finish. Didn’t have to spend much time here.

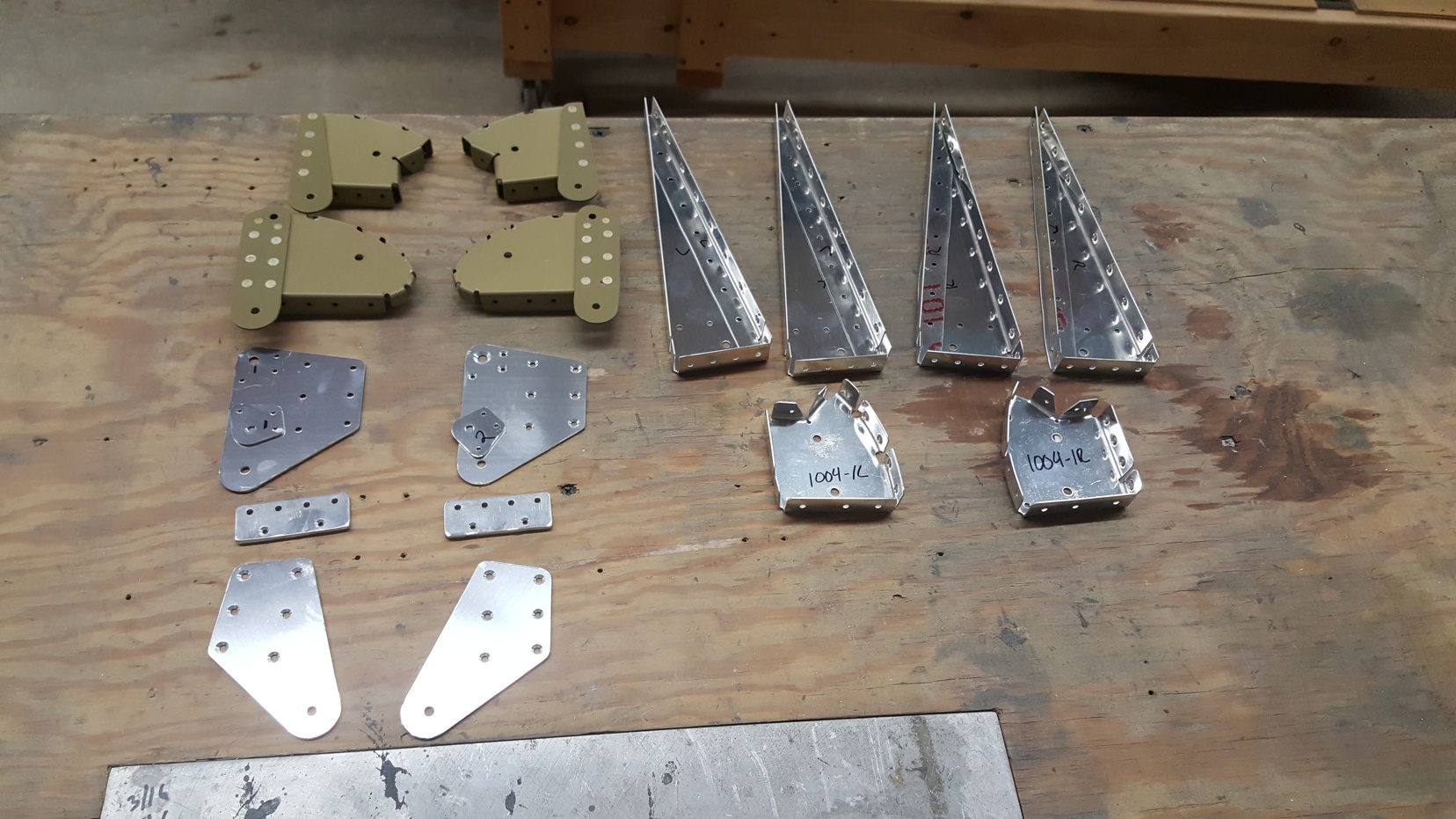

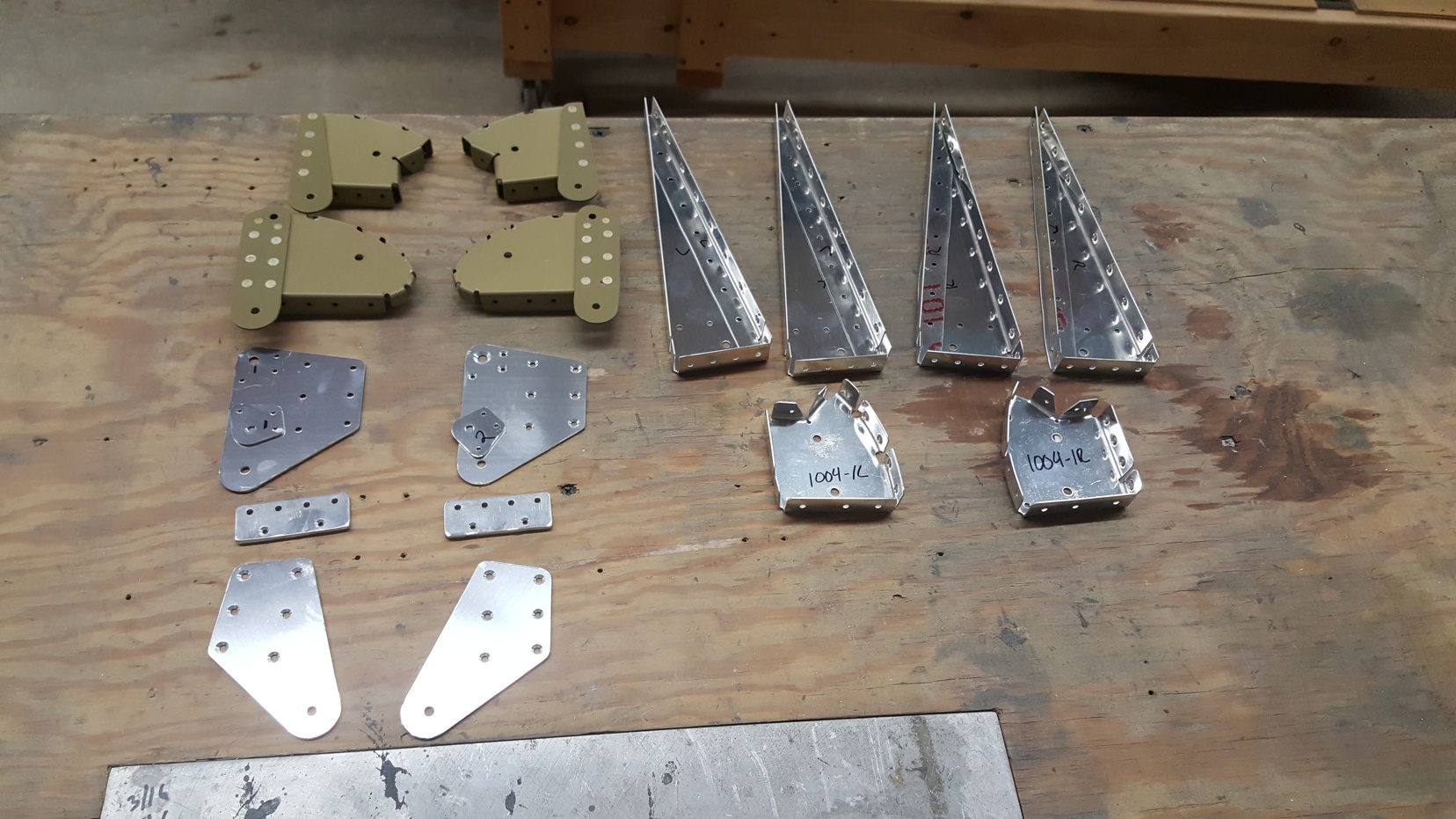

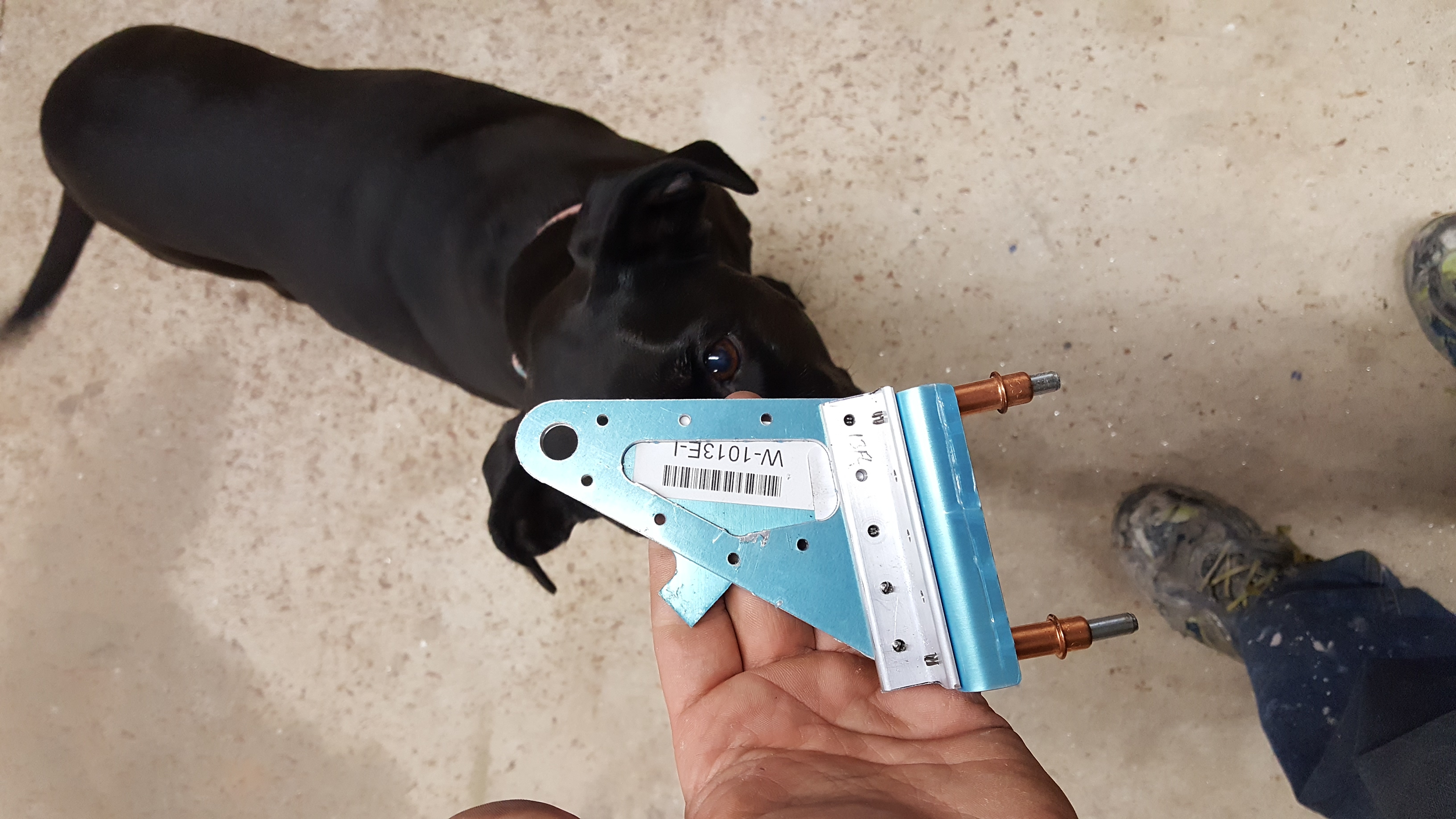

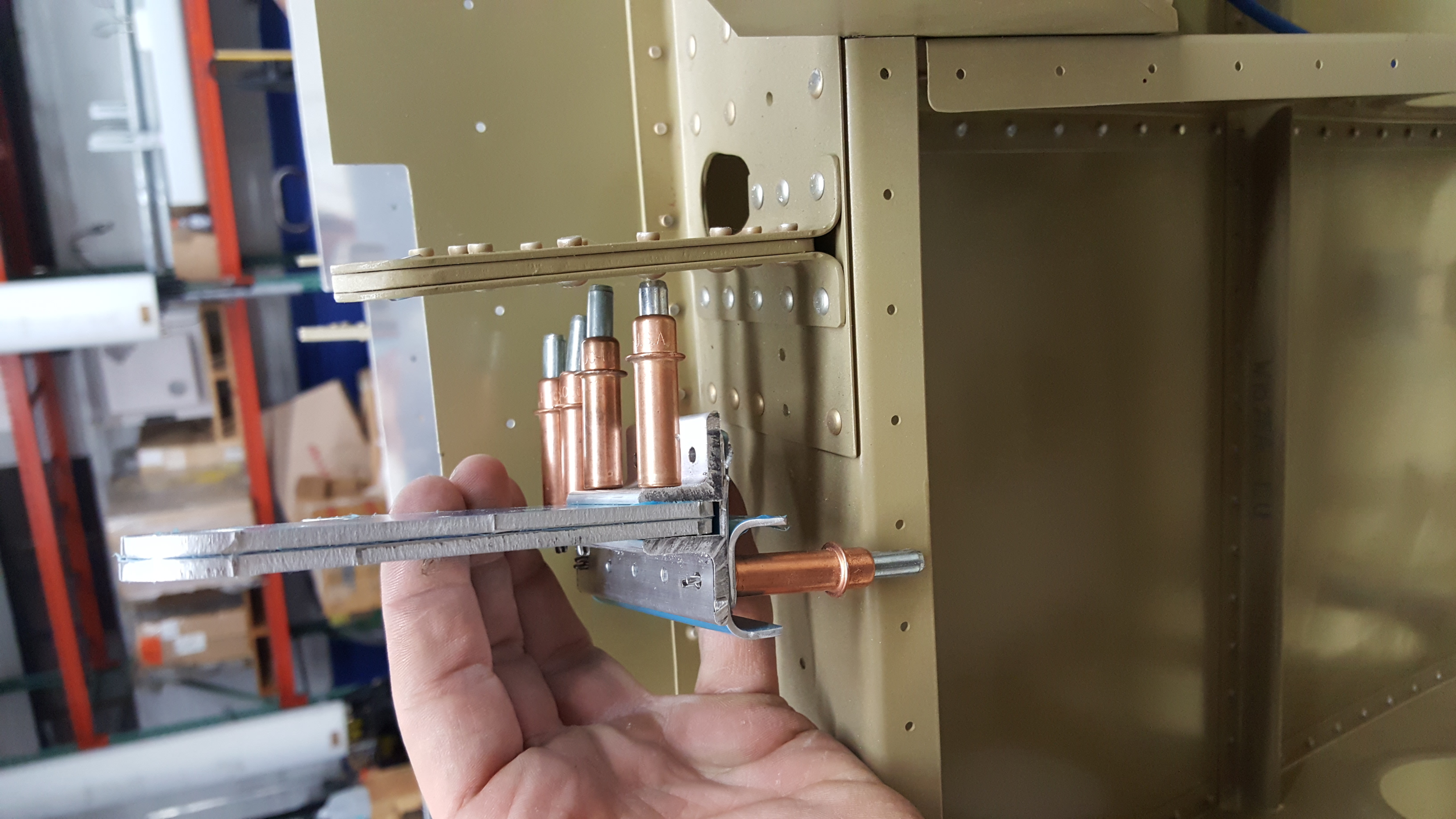

Next I decided to go ahead and start working on the ailerons since I have YET to finish the fuel tanks. Might as well keep chugging and keep the motivation train going. I probably spent a good hour here, just looking for parts that were 3 feet away from me. On top of my instruction book. It is amazing how easily things disappear when you look everywhere else. This first page went really quick, I was able to cut, debur, drill, counter sink, sand, & prime pretty quickly.

Once these parts were dry, I quickly riveted them together. I did have a hard time locating the nutplates. I searched through the parts list about 5 times, search on vansairforce to see if anyone else had them. Priced them out on aircraft spruce, and finally sat down to eat my pizza that got delivered and the part # jumped at me on the page that was open. They are in bag 1219 if you run across the same issue I did.

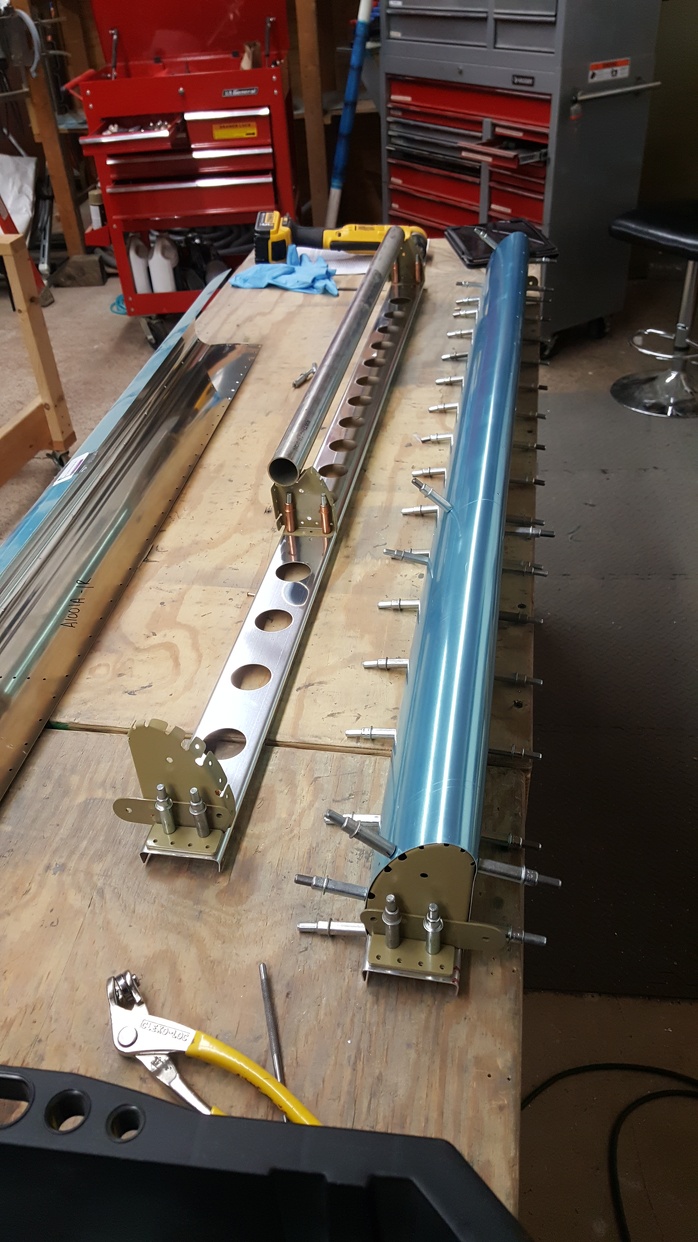

Next I began by cutting the aileron ribs. the ailerons only have 2 on each, one on each end. the rest are actually just stiffeners.

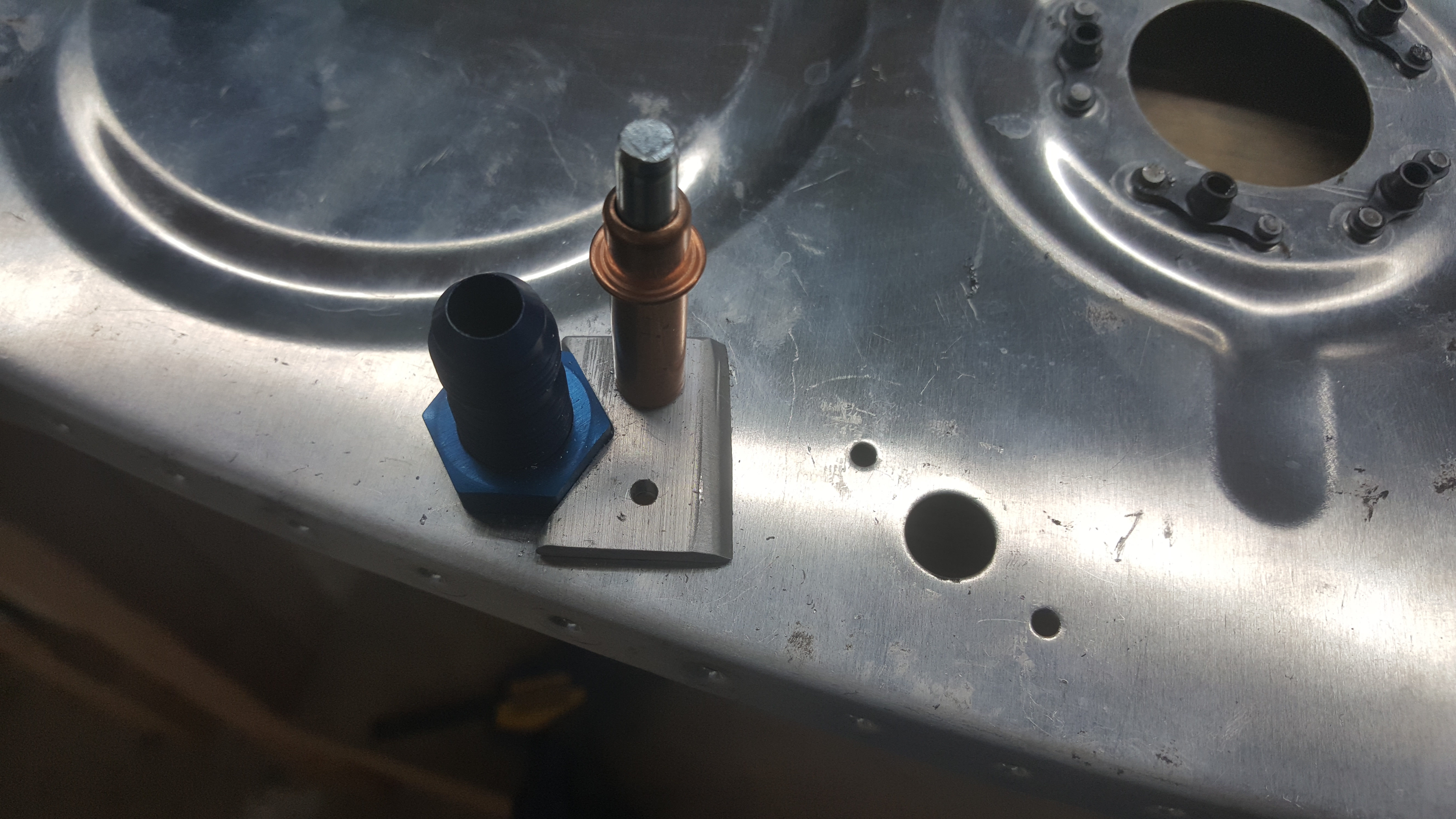

Next I dimpled all the holes I could as requested by the plans. I noticed here that the plan steps do not mentioning dimpling the #30 holes, but one of the figures calls for a 120* dimple. I ended up ordering #30 120* dimple set from Cleveland Aircraft tools. I was ready to call it a night when the plans said I could primer everything. so I cleaned everything up.