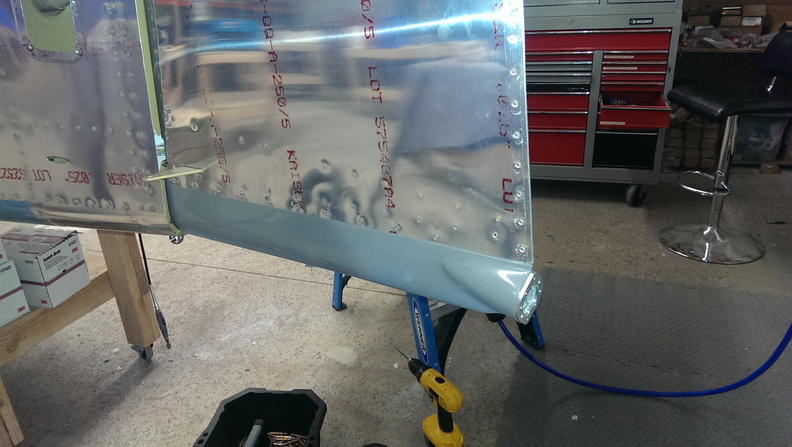

Poor logging this week, but Ill get over it. Last week I ordered a bunch of spare rivets, some NACA ducts, flanges and hoses for the cabin air that will be installed later. Turns out I ordered the wrong flanges but its not the end of the world. First thing I did was install the ball joints into the elevators. The plans call for a 7/8″ gap from the center of the hole to the front spar of the elevator. This was pretty easy.

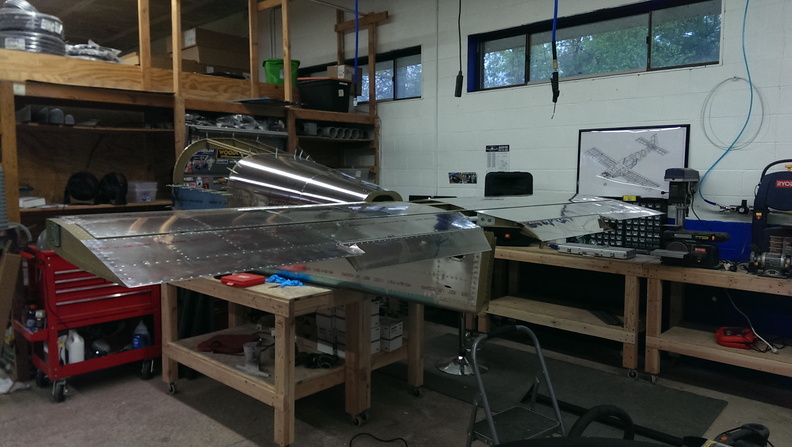

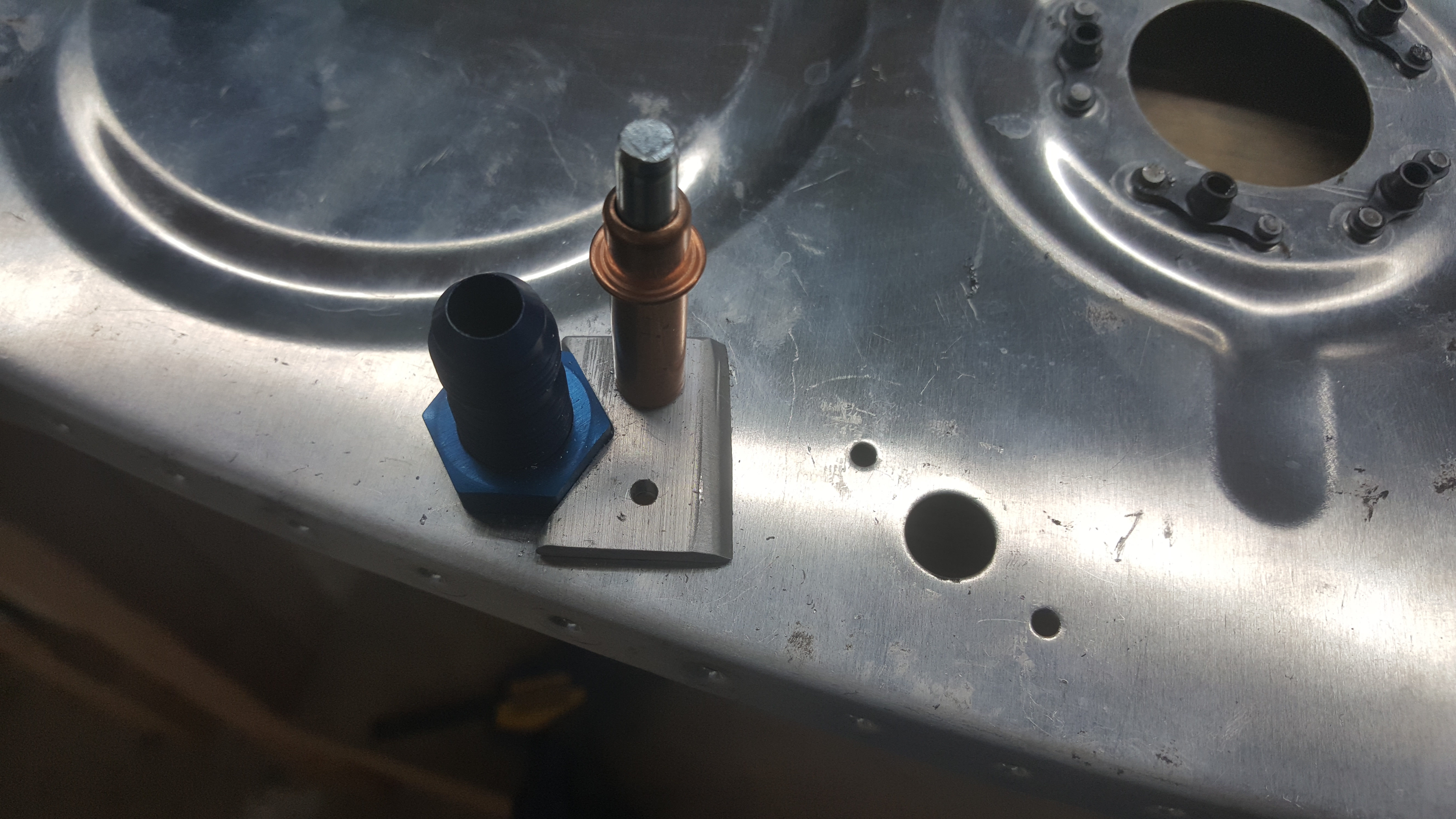

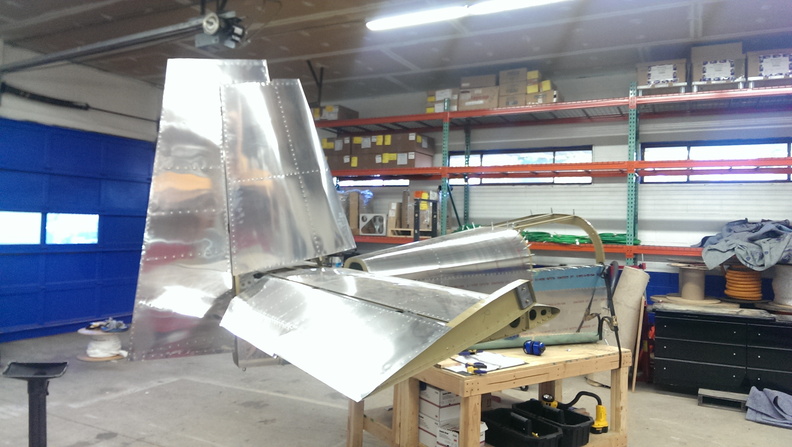

next I mounted the horizontal stabilizer to one of the many workbenches I had with 4 Sheetrock screws. Next I mounted one of the elevators to the horizontal stabilizer and made sure I had the clearances needed. then I had to file down a bushing so it would fit in the bearing to drill the final pivot point. after a quick trip to a local tooling shop, I was able to drill the hole in the control horns. Rinse wash repeat for the other side.

after mounting both elevators back on I marked and drilled the control horns for the push rod. the plans next call for the elevators to be removed. but I was in no mood to do that considering how much of a PITA it was to get the nuts tightened on there.

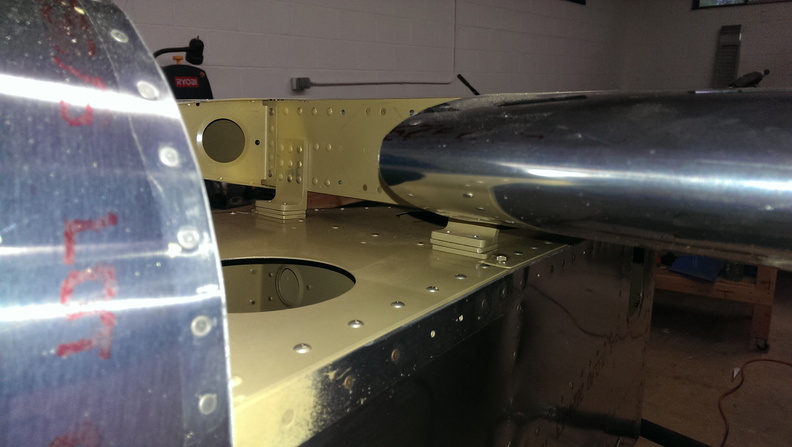

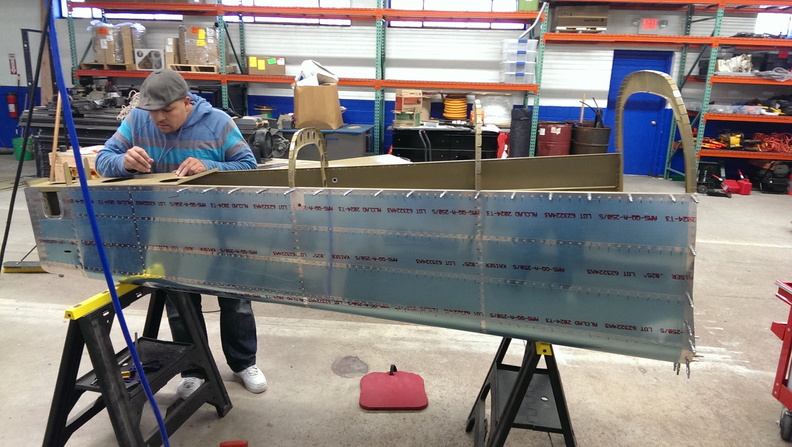

I believe next I match drilled the Vertical Stabilizer attach bracket and made the spacers for the horizontal stabilizer.

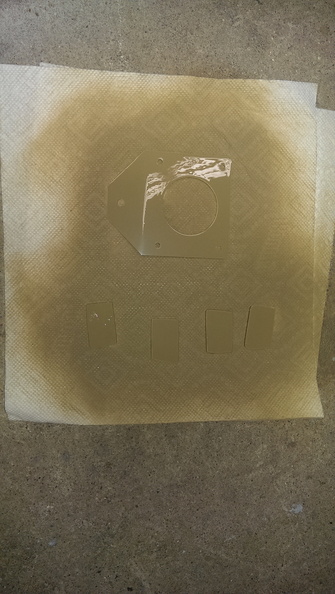

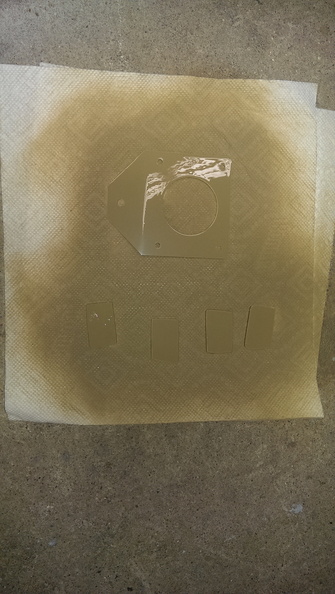

spacers made from the plans (photocopied 4 times) for templates

parts primed

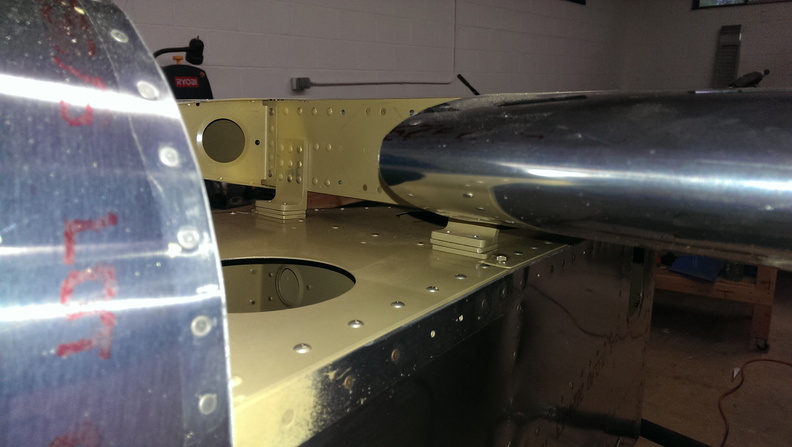

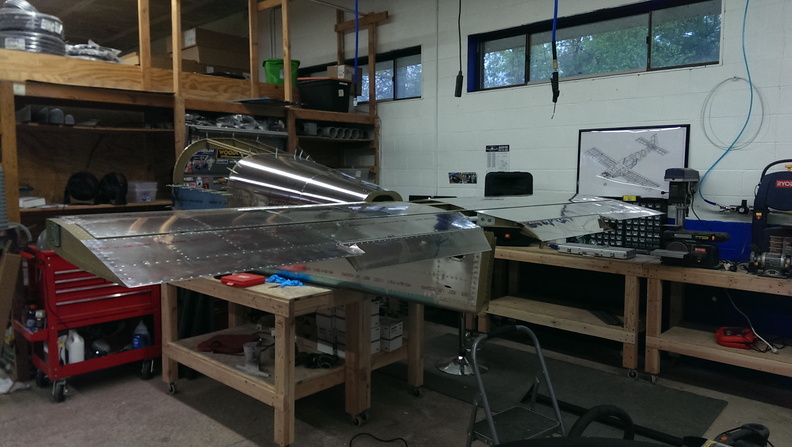

Once these parts dried, I taped the spacers onto the bottom of the HS attach brackets. Next i mounted the HS Assembly onto the tailcone. I finished the day off by match drilling the 4 attach points towards the rear. I installed the nuts & bolts as called out in the plans as I drilled each hole.