Today I began the fun process of dimpling and priming. There must be more holes in the rudder skins than the entire vertical stabilizer combined. I’m sure ill say that about something else later. The cleaning process was the same, soap, rinse, acid, rinse. I let the acid sit for 35 minutes. Once I was able to make sure the parts were all dry I grabbed a can of SEM EZCoat. This stuff is the bee’s knees (yeah I went there). I swear it dries the second it is applied to the part. I still give it about a half hour to dry prior to flipping it over and doing the backsides. I fully intended to stop here, but I couldn’t I stop. I decided to rivet a few small pieces. So now I’ve riveted the R1004s to the rudder horn, the spar stiffners, as well as the nut plates. I stopped there as I wanted to make sure the skins dried over night as they were the last pieces I primed.

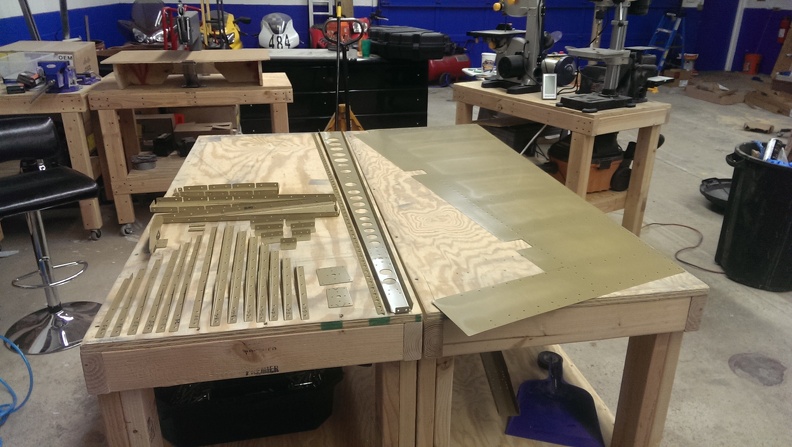

Dimpled, Ready to prime

Parts primed

Riveted parts