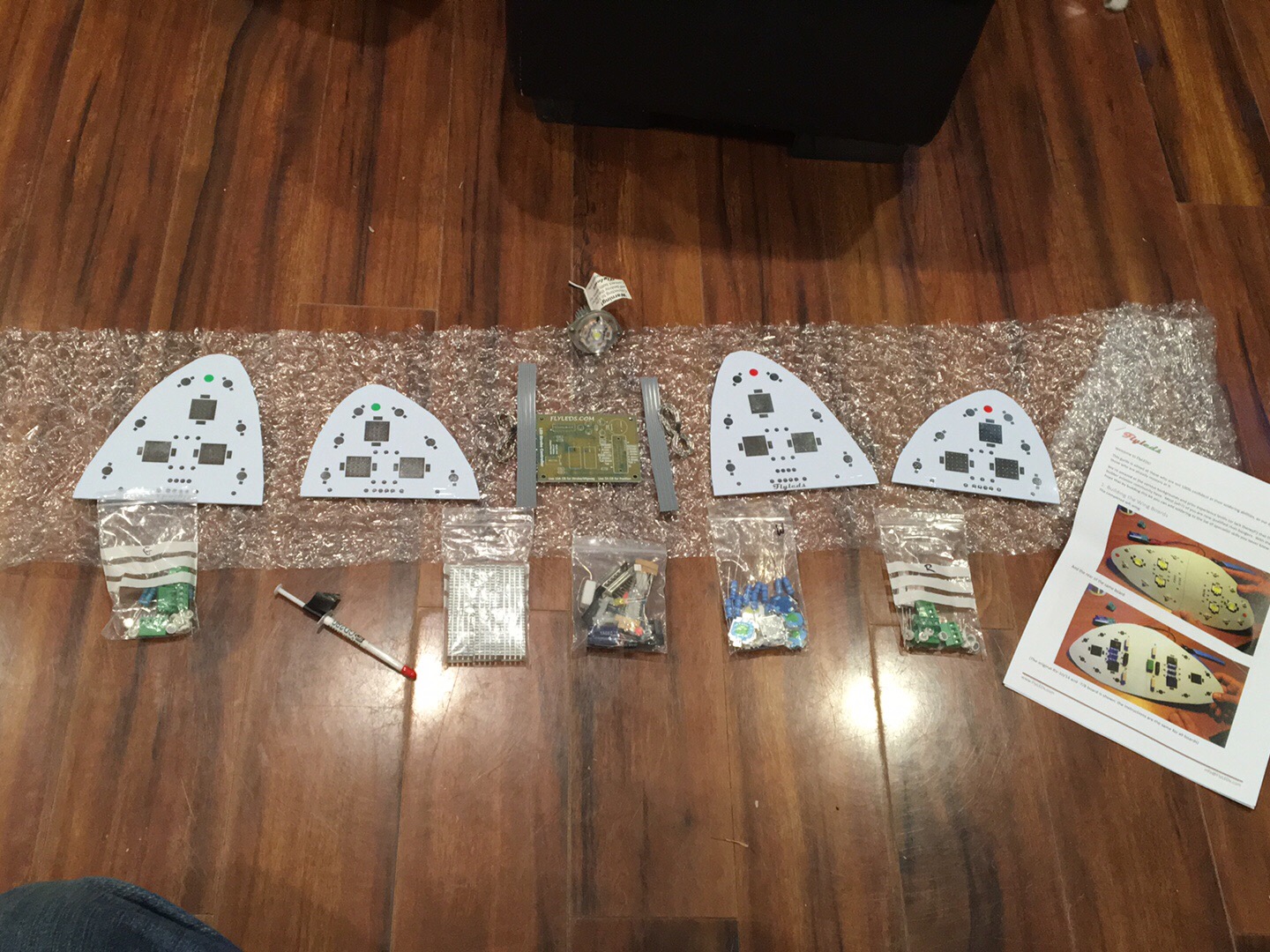

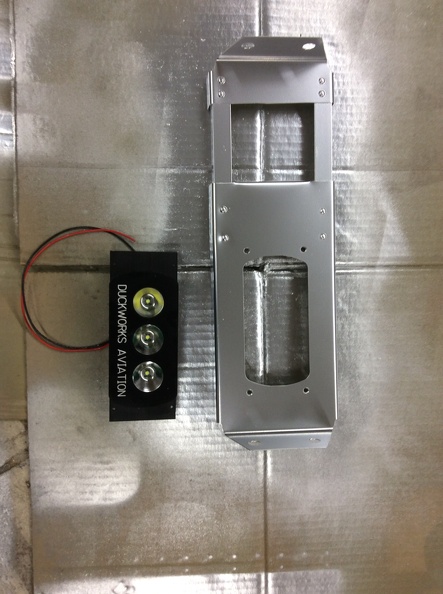

Like many builders before me, I have been trapped by the events of life and all flying related activities were suspended for quite some time. Fortunately things are working in my favor again and its time to blow the dust off the project. I started by cleaning out the work area. Now that I can work again i started looking over where I left off at with the left fuel tank. After staring at it for a bit I elected to reorder a bunch of parts and redo it as I am not happy with it. On May 7th I ordered my nav / positioning / tail lights from FlyLEDS.com. Paul was very communicative and incredibly fast at sending them out. He told me it would take about 10 days to get here from Australia. On May 19th I checked the mail and here they were.

Last night I decided to start putting these lights together. Paul sends very detailed color instructions. Its been quite a while since I had to solder, but I think I did a good job. You start off by folding the tabs on the LEDs.

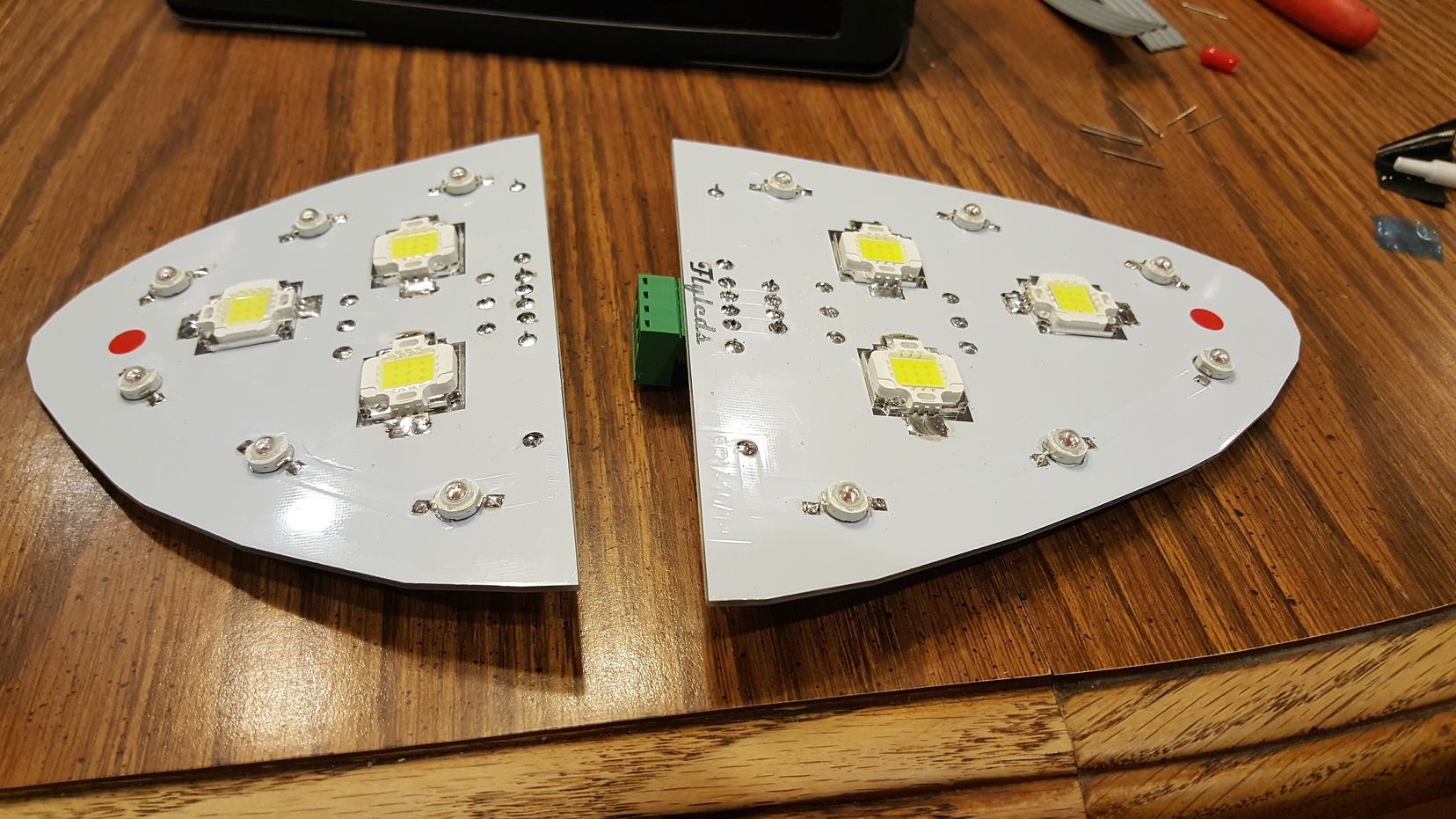

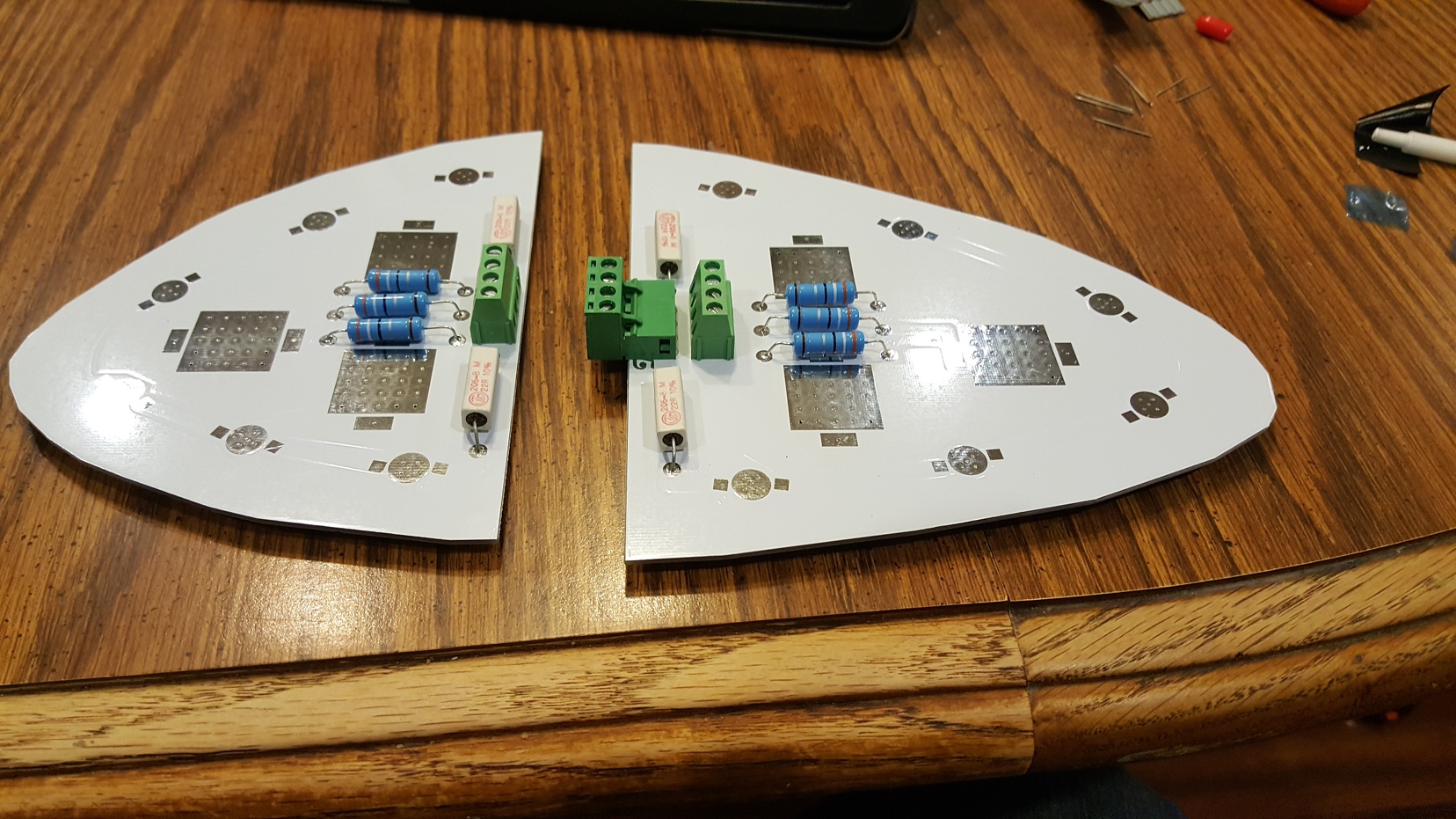

Then I soldered on the White LEDs and the Red LEDs. after that its followed by soldering in a bunch of resistors and a few connectors.

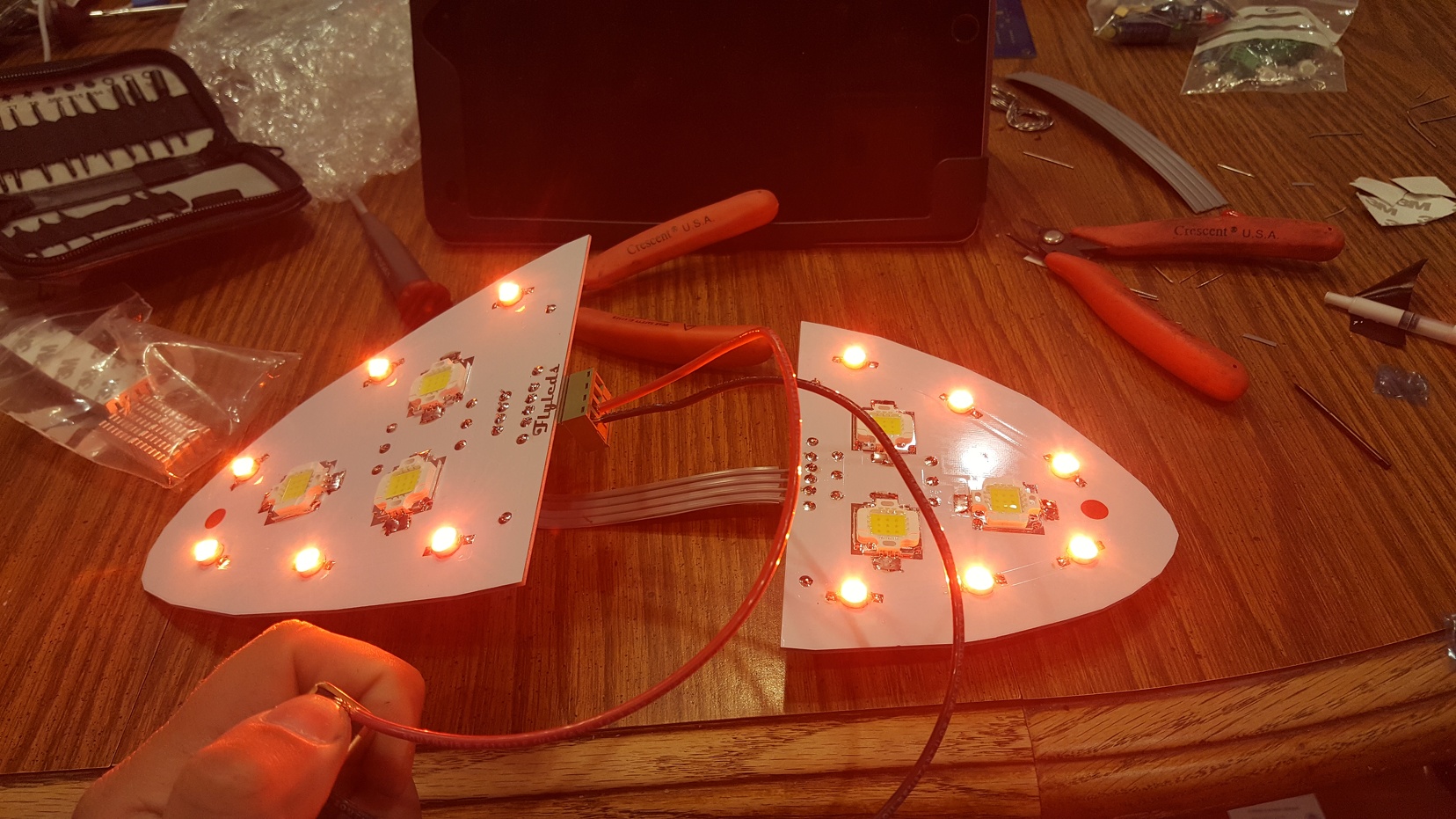

After this was all put together, I had to test it. The instructions say its okay to use a 9V battery but it won’t be as bright as it would be with a 12V battery. All I can say is they are bright. The camera does not pickup the amount of light these put out at all

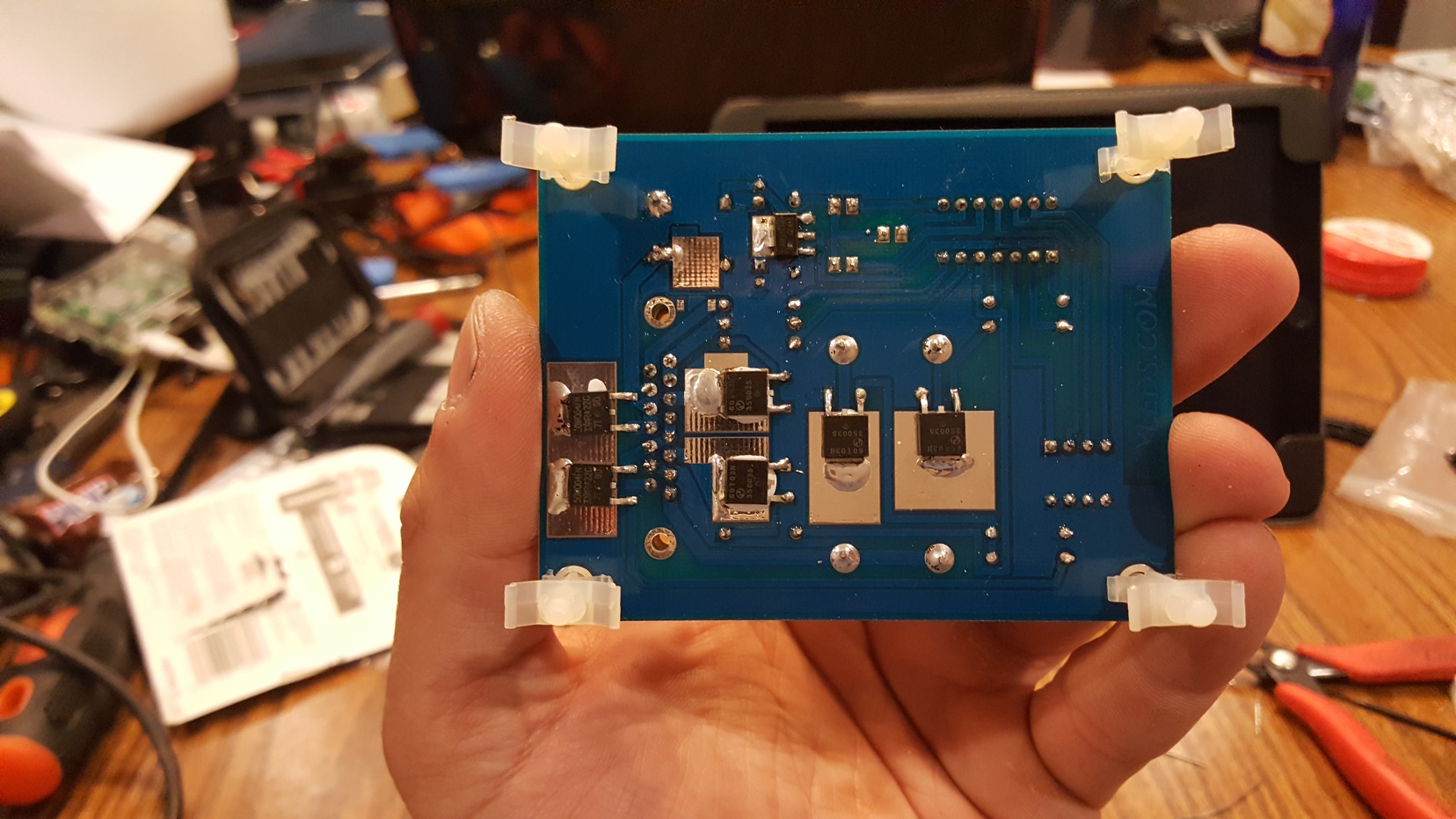

I followed this up with the right side (green) which was the same exact process. After that I put together the controller board. This had a lot of pieces to put together, and I haven’t had the opportunity to test it yet.